Completed custom-built high-temperature kiln with integrated instrumentation, viewing ports, and safety enclosure.

Overview

This project involved the design and fabrication of a large, custom-built high-temperature kiln intended for glass work and experimental firing. The goal was to create a durable, serviceable system capable of sustained high temperatures while remaining accessible, observable, and safe to operate.

Rather than adapting an existing commercial unit, the kiln was built from the ground up to meet specific size, thermal, and control requirements.

Design Goals

- Large internal volume with uniform heat distribution

- Continuous operation at high temperatures

- Direct visual monitoring during firing

- Robust structural enclosure for safety

- Modular construction for maintenance and repair

Every design decision prioritized reliability, serviceability, and long-term use.

High-temperature viewing port during operation, allowing direct visual monitoring of internal conditions.

Observation & Control

Multiple viewing ports were integrated into the kiln body, allowing real-time visual inspection during firing. This capability is especially valuable when working with glass, where surface condition and heat behavior provide critical feedback that instruments alone cannot.

Instrumentation was positioned for clear readability and easy access, supporting precise control throughout the firing process.

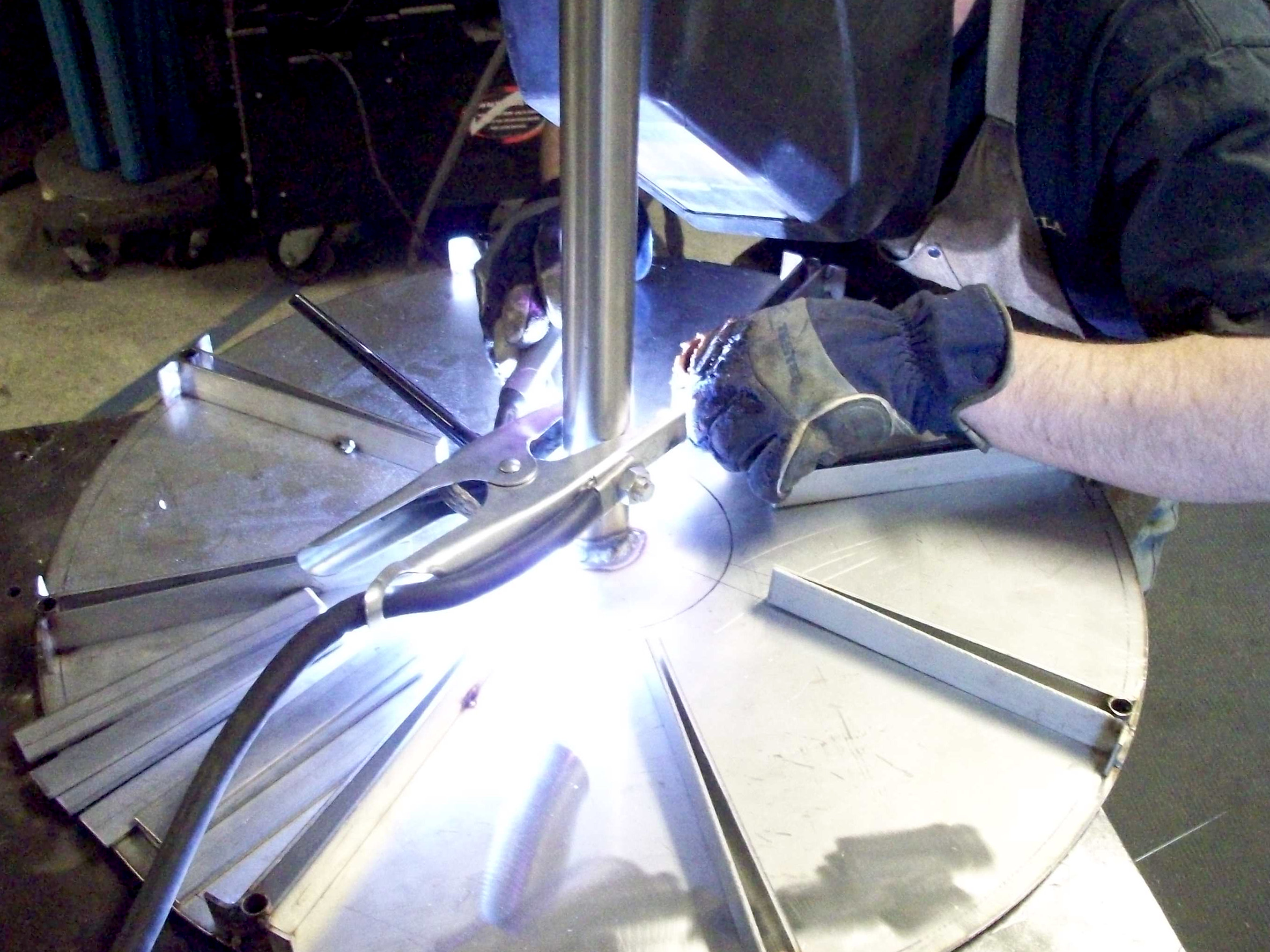

Fabrication of internal components during assembly, showing structural and mechanical details.

Fabrication & Assembly

The kiln structure was fabricated using welded steel components, designed to support both the refractory mass and the operational stresses of repeated thermal cycling.

Care was taken to maintain alignment, rigidity, and accessibility throughout the build. Components were assembled in stages to allow inspection, adjustment, and future disassembly if required.

Interior refractory lining with embedded heating elements prior to final assembly.

Interior Construction

The interior lining consists of layered refractory materials designed for insulation, durability, and consistent thermal performance. Heating elements were embedded and routed to ensure even heat distribution throughout the chamber.

Attention was given to minimizing thermal gradients and providing predictable firing behavior across the full working volume.

Loading large glass work into the kiln prior to firing.

Operation & Use

The finished kiln has been used for large-scale glass work and experimental firings, supporting pieces that would be impractical or impossible in standard commercial units.

Its size, visibility, and control capabilities make it especially well suited for iterative processes, where observation and adjustment are key to achieving desired results.

Outcome

This kiln has proven to be a reliable and versatile tool, capable of sustained high-temperature operation while remaining approachable to use and maintain. The project demonstrates a balance between heavy fabrication, thermal design, and practical usability.

It stands as an example of purpose-built equipment designed to serve real-world creative and technical needs.